Project Summary

Nano-scaled materials are abundant in different stages of industrial manufacturing. Physical and chemical properties of these materials are strongly dependent on their size. Characterisation of mean size, size distribution, and shape of nano-scaled particles is very critical for the quality and efficiency of manufacturing processes. Yet, conventional characterisation technologies still show manifold shortcomings which represent a major innovation obstacle for manufacturers of nanoparticles.

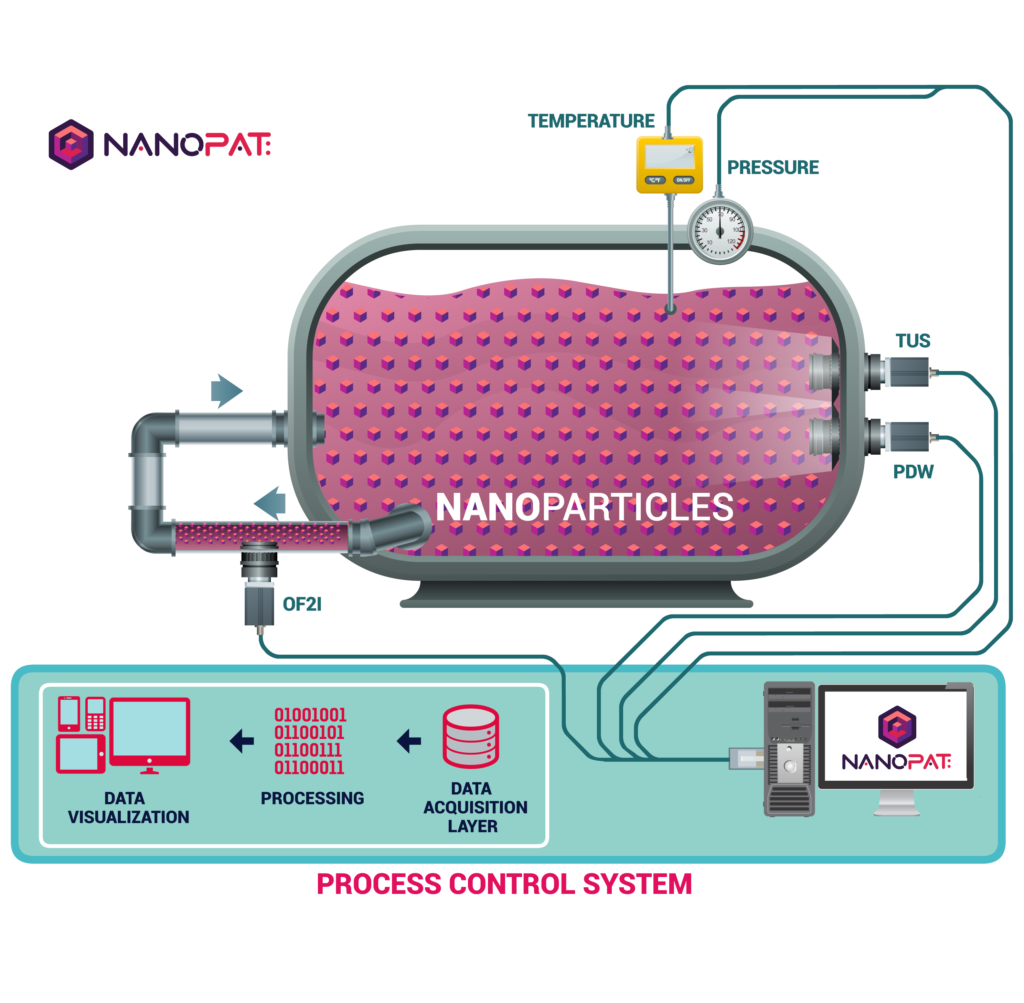

The NanoPAT consortium aims at closing this gap by the demonstration of 3 novel, real-time nano-characterisation Process Analytical Technologies (PAT), namely Photon Density Wave spectroscopy (PDW), OptoFluidic force induction (OF2i) and Turbidity Spectrometry (TUS) including real-time data handling for digital process monitoring and product quality control.